But the industries that are pursuing Industry 4.0 ideals the hardest make extensive use of GD&T. Millions of parts are made every year with simple basic dimensions and tolerances, and they work. MBD Dimensions can be mundane size or location tolerances, or they can be more complicated GD&T type tolerances. Technology is still in its infancy, it is very promising. This is a major milestone toward smart manufacturing, and while the The good news is that both SOLIDWORKS CAMĪnd CAMWorks can add tolerance windows to their criteria for strategy Where we want to be (fully automated manufacturing), the tolerance must be If its tolerance is +/- 0.010 inches vs +/-0.0005 inches, so in order to get to Wasn’t listed above and it may be the single most significant factor whenĬhoosing how to cut a part! The same physical feature will be cut differently This is called knowledge-based machiningĪnd, when implemented right, it reduces programming time tremendously while

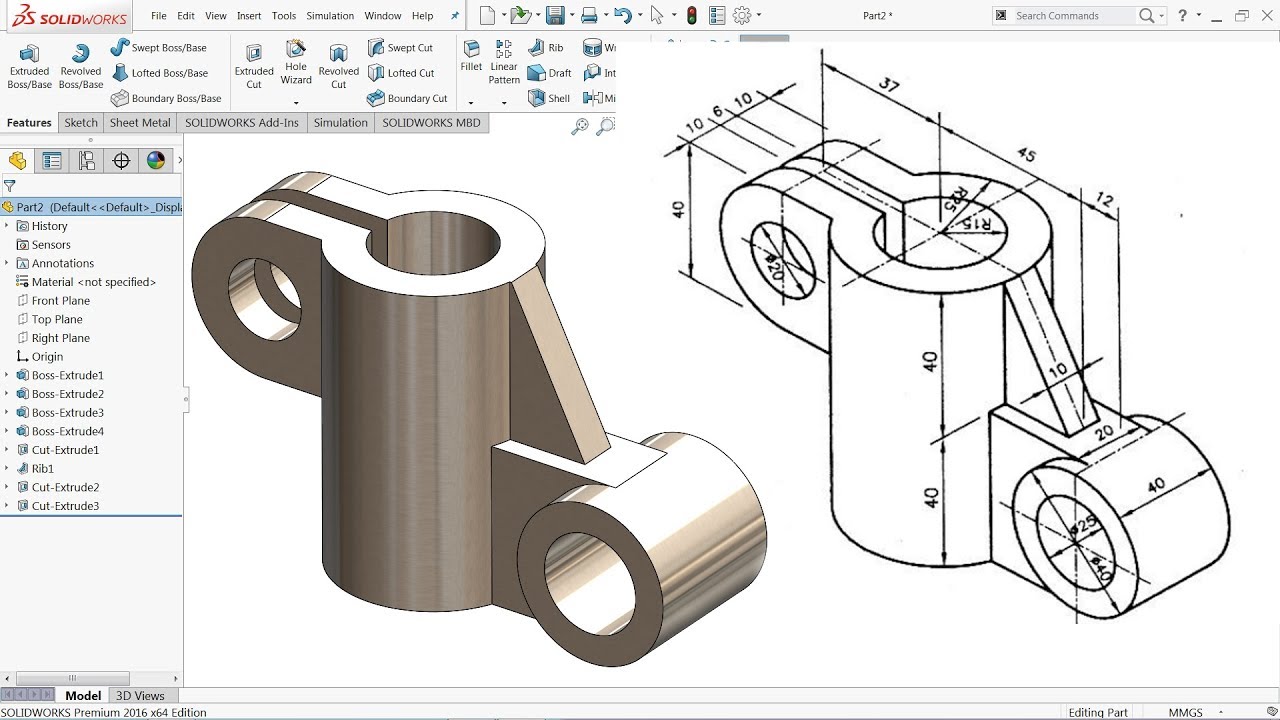

To the programmer based on the feature’s parameters and what the programmer However, in SOLIDWORKS CAM, a strategy is suggested The success of this process is a function of the Instinctually programmers assess their parts for machinableįeatures, weigh the significance of the parameters above, and then develop a Programmers to interpret the dimensions of 2D drawings and devise a plan for That they are packed full of data ready to be leveraged. So SOLIDWORKS CAM features are “smart” in Rectangular, obround, irregular or wrapped? Several parameters about each of these features: There are many types of features, and the software understands how they differ from each other: In SOLIDWORKS CAM, which is powered by CAMWorks, the fundamental unit is a feature.

On the road toward machine tools that can predict inspection failures, we must first reach a point where software understands what a tolerance is, how to read it, and how to target it.Īnd it just so happens that SOLIDWORKS CAM’s feature-based approach provides the necessary structure for tolerances to be presented to the manufacturing software (in this case, it is the software creating cutting paths). And this is where tolerance-based machining enters the picture. In the timeline between the third and fourth Industrial Revolutions, we are at the stage of knowing what needs to be done, and actively working to meet the many “prerequisites” like those above. This might show up as an irregular pattern in a servo motor’s torque curve, or the machine base vibrating at a resonant frequency. For this scenario to come to fruition, several prerequisites must be met-for example, the machine tool must collect data that signals an impending defect. But to be considered smart, I would expect the equipment to anticipate an out-of-tolerance situation and hedge against the defect before it ever exists.

0 kommentar(er)

0 kommentar(er)